3 Online Courses (3-6 hours)

Our Basics series provides participants with a general understanding of the three major aspects of injection molding; the injection molding machine, the molding process, and the injection mold. These programs use 3D animation to demonstrate the inner workings of the machine and mold and to easily convey otherwise complex concepts. Important safety precautions are stressed throughout these training programs.

These basic injection molding training programs are ideal for new hires, yet also serve as an excellent refresher course for any employee involved in plastics processing; from operators and technicians to management and setup personnel.

Part 1: Machine

These basic injection molding training programs are ideal for new hires, yet also serve as an excellent refresher course for any employee involved in plastics processing; from operators and technicians to management and setup personnel.

Part 1: Machine

- Cites important safety precautions for working around injection molding machines

- Gives an introduction to the injection molding process

- Introduces machine types and the different modes of operation

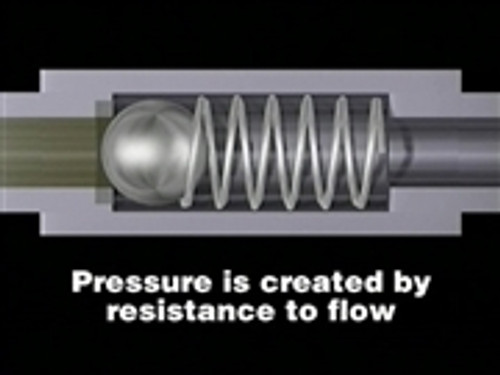

- Discusses injection molding machine components and their respective functions

- General procedures for starting up and shutting down a molding machine

Part 2: Process

- Discusses polymers and the three criteria used to classify them

- Covers some of the more common procedures for material preparation

- Introduces the three phases of the molding process; injection, cooling and ejection

- Explains the need for maintaining an accurate process log

- Defines common injection molded part defects and explains their causes

Part 3: Mold

- Explains the specific functions that an injection mold must perform

- Introduces the various machining methods used to construct an injection mold

- Discusses the three mold configurations used in the industry

- Covers common runner shapes and gate types used in injection molds

- Gives an overview of proper injection mold maintenance