Our two Electric Injection Molding courses will provide participants with a better understanding of the benefits and capabilities of modern all-electric injection molding machines. Safety concerns particular to electric molding machines are also covered.

1: Understanding Electric Injection Molding Machines

This training program will provide participants with a better understanding of how electric injection molding machines function – as well as the many benefits and capabilities associated with electric molding machines.

- General Injection Molding Safety

- Electric Molding Machine Safety

- Machine Guarding

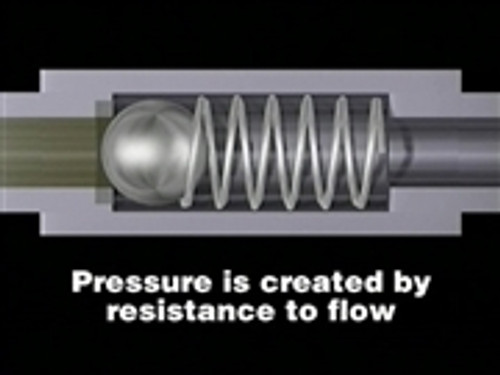

- Comparing Hydraulic and Electric Machines

- Basic Molding Machine Functions

- Efficiency, Accuracy and Repeatability

- Alternative Machine Designs

- Typical Uses for Electric Injection Molding Machines

2: Processing with Electric Injection Molding Machines

Packed with in-depth processing information, this course will undoubtedly prepare processors for making more appropriate and cost-effective decisions. Participants will also learn how to optimize any process that’s running on an electric injection molding machine.

- Closed-Loop Process Controls

- Hydraulic vs. Electric Molding Machine Controls

- Process Optimization Strategies:

- 1st Stage Filling

- 1st Stage to 2nd Stage Transfer

- 2nd Stage Pack

- Screw Delay

- Screw Recovery

- Screw Decompression

- Cooling Time

- Mold Opening

- Part Ejection

- Mold Closing

- Clamping